Everything you need to know about visibility, regulations, and quality control with reflectometry

In work environments where visibility is a key safety factor, having high-visibility clothing is not only recommended but legally mandatory. However, wearing fluorescent garments or those with reflective bands is not enough. The real guarantee of safety lies in regulatory compliance and the ability to accurately measure retroreflection levels using specialized instruments such as a reflection photometer or retroreflectometers.

In this article, we explain what reflectometry tests consist of, which regulations govern reflective clothing, and how at T2S Ibérica we offer the technology and equipment necessary to ensure that your high-visibility clothing meets the highest safety standards.

What is reflectometry applied to reflective clothing?

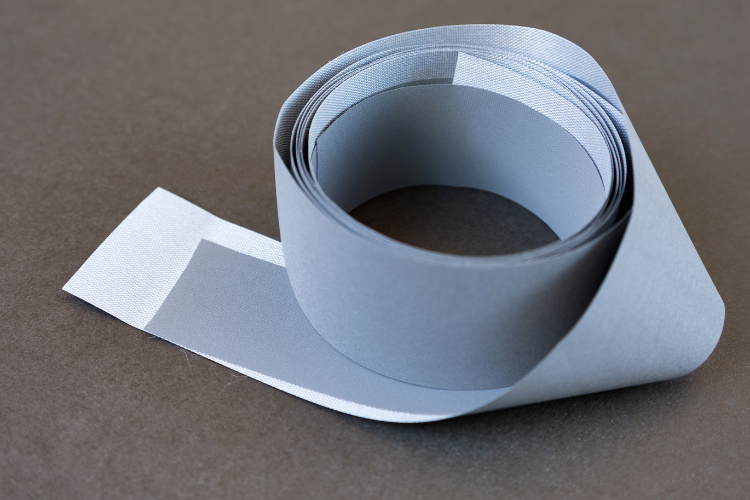

Reflectometry is the technique used to measure a surface’s ability to reflect light, especially in the same direction as the emitting source. In the context of high-visibility clothing, this measurement is crucial to ensure that the retroreflective bands applied to workwear meet the required illumination and reflection levels set by European regulations.

Reflectometry tests are conducted using a professional instrument called a reflection photometer or retroreflectometer, which allows quantifying the intensity with which a reflective band returns light to its source, even under low visibility conditions.

What regulations govern reflectometry tests for high-visibility clothing?

High-visibility clothing is regulated by the EN ISO 20471 standard, which sets the technical requirements for a garment to be considered suitable as personal protective equipment (PPE) in hazardous environments. This standard focuses on aspects such as:

Additionally, other standards such as EN ISO 13688 (general requirements for protective clothing) complement the criteria to ensure safety and durability.

How is the effectiveness of reflective clothing controlled with reflectometry tests?

To ensure that garments maintain their reflective properties over time, periodic measurements are necessary. This is where reflectometry and the use of reflection photometers or reflectometers are essential. These devices are key to guaranteeing that high-visibility garments meet the required safety standards.

Thanks to reflectometry, it is possible to objectively verify whether the reflective bands provide the necessary level of retroreflection to protect workers in low-light environments or adverse weather conditions. This evaluation is essential both in manufacturing processes and in post-use quality controls, as over time and with wear, the reflective material can lose effectiveness.

At T2S Ibérica we offer retroreflectometers with DELTA technology, ideal for quality control both during the manufacturing process and throughout the prolonged use of the garments.

Related articles

Reflectometry tests for reflective clothing: Advantages of using a reflection photometer

Conducting reflectometry tests periodically is essential to ensure that high-visibility clothing maintains its retroreflective properties over time and under real-use conditions.

This measurement is key both for manufacturers and for companies that must guarantee the safety of their personnel exposed to low-light environments or high-risk situations. The advantages of conducting reflectometry tests in professional settings are:

Practical applications of reflectometry in work sectors

At T2S Ibérica we are official distributors of reflectance measurement equipment from DELTA, a leader in precision instruments for road and workplace safety.

The DELTA technology retroreflectometers allow for reflectometry testing to accurately measure the retroreflection of reflective bands on work garments. It is portable, ergonomic, and compatible with analysis software, making it the perfect tool for:

You can consult all models of DELTA vertical and horizontal reflectometers, available in the T2S Ibérica catalog, to perform reflectometry tests on technical reflective clothing.

T2S Ibérica: Your partner in safety, visibility, and technology

At T2S Ibérica, we have over 30 years of expertise in high-visibility workwear and technologies applied to road and professional safety. In addition to offering a wide catalog of certified reflective clothing, we also provide tools such as retroreflectometers to ensure your garments continue to perform their protective function.

Do you have questions about which reflection photometer you need or how to incorporate reflectometry into your company? Contact our team of experts, and we will help you improve your quality control and occupational safety system.

Contact us