Pioneers in road safety

and personal protection

WIDE RANGE OF TECHNICAL

FOCUSED ON SAVING LIVES

WIDE RANGE OF TECHNICAL

FOCUSED ON SAVING LIVES

They trust us:

Welcome to T2Siberica

T2S IBÉRICA is the reference company in retroreflective materials in Spain and Portugal. Since its foundation in 1991, its objective has been to lead the sector of this type of materials, becoming nowadays a reference.

We have contributed and are contributing to the advancement of road safety in Spain, advising public and private entities, putting all the technological advances of retroreflective materials at the service of road and personal safety.

T2S IBÉRICA manufactures, markets and distributes high visibility PPE garments and retro-reflective materials for road signs, beacons and vehicle markings.

Categories

OUR RANGE OF SOLUTIONS

T2S presents an extensive range of high visibility workwear, designed to ensure safety and comfort in a variety of work environments.

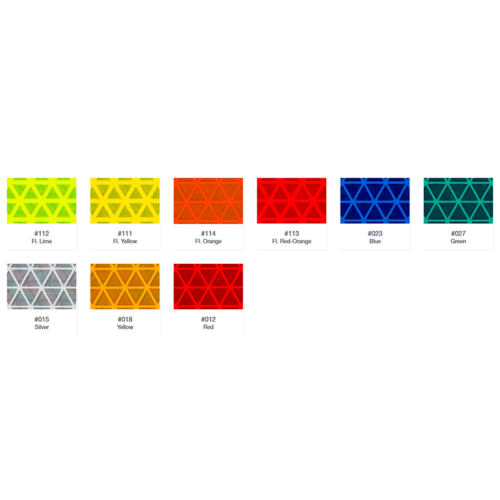

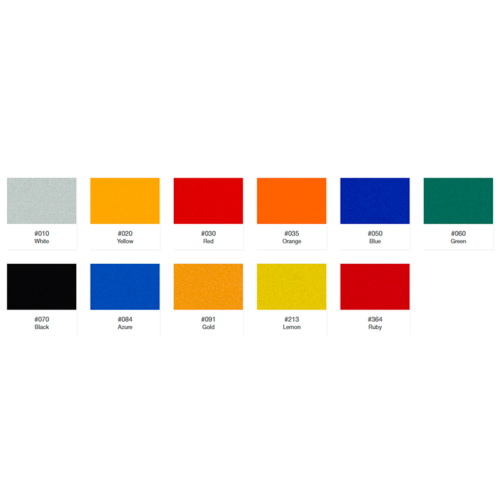

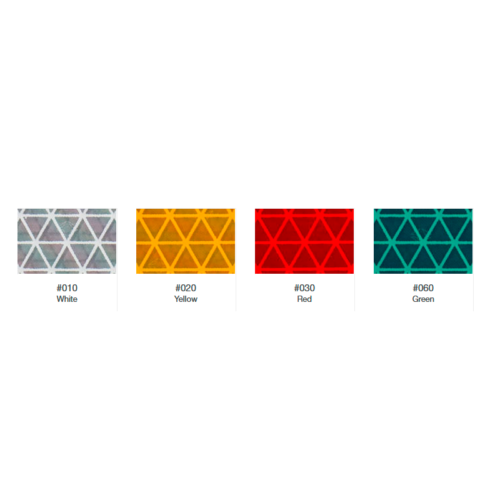

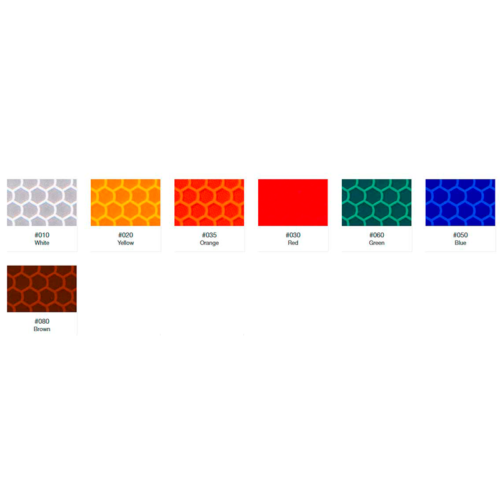

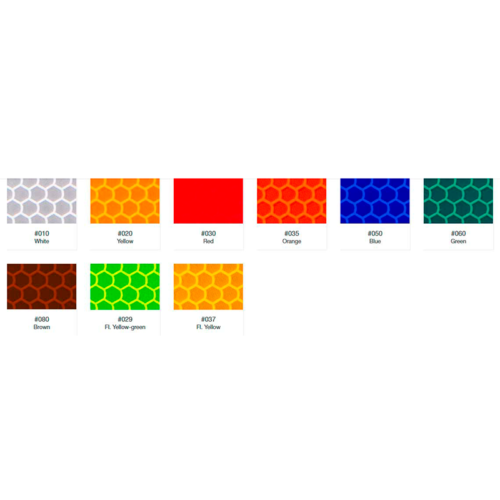

We offer a wide variety of retroreflective tapes. We are always thinking of satisfying all the current safety and all of the visibility needs.

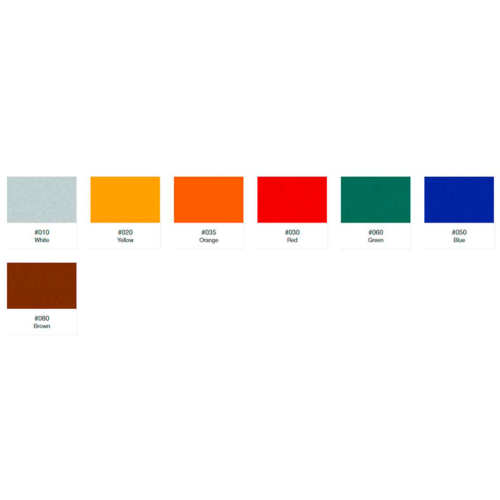

T2S offers a variety of retroreflective sheeting, ideal for signaling and safety applications, improving visibility in multiple conditions.

T2S provides advanced vehicle wrapping solutions, offering customized and high-quality options to enhance visibility and corporate image.

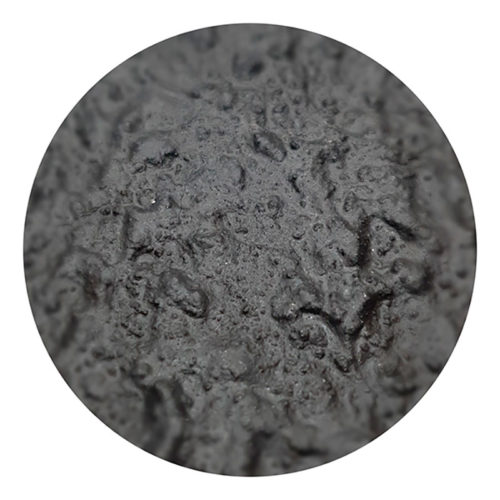

T2S supplies specialized materials for asphalt repair, ensuring long-lasting and effective solutions for the maintenance of roads and surfaces.

Categories

OUR RANGE OF SOLUTIONS

T2S presents an extensive range of high visibility workwear, designed to ensure safety and comfort in a variety of work environments.

We have a wide variety of retro-reflective tapes, always thinking of satisfying all the current safety and all the visibility needs.

T2S offers a variety of retroreflective sheeting, ideal for signaling and safety applications, improving visibility in multiple conditions.

T2S provides advanced vehicle wrapping solutions, offering customized and high-quality options to enhance visibility and corporate image.

T2S supplies specialized materials for asphalt repair, ensuring long-lasting and effective solutions for the maintenance of roads and surfaces.

Featured Products

Explore our wide range of specialized products and find exactly what you need for your working environment. If required, please ask for information without any obligation.

Featured products

Explore our wide range of specialized products and find exactly what you need for your working environment. If required, please ask for information without any obligation.

Contact with us

We are here to assist you with all your inquiries and needs. Please complete the following contact form and our team will contact you as soon as possible. What do you need?